3D printing

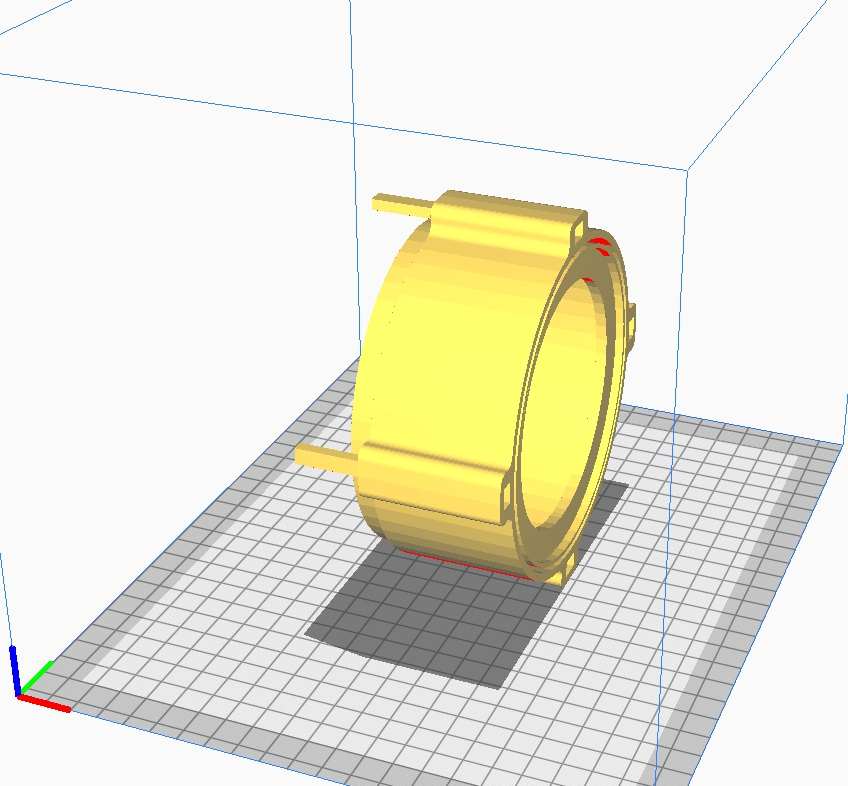

As the designing is completed , now time comes for 3d printing so i can validate interconnectivity btw my design

For this i went through 3 different type of printer

1. Anet A2 plus

2. Makerbot Z18

3. Stratsys F370

Starting with anet a2 plus , as this is is my personal printer so i thought that i can easily work with my prints from my home

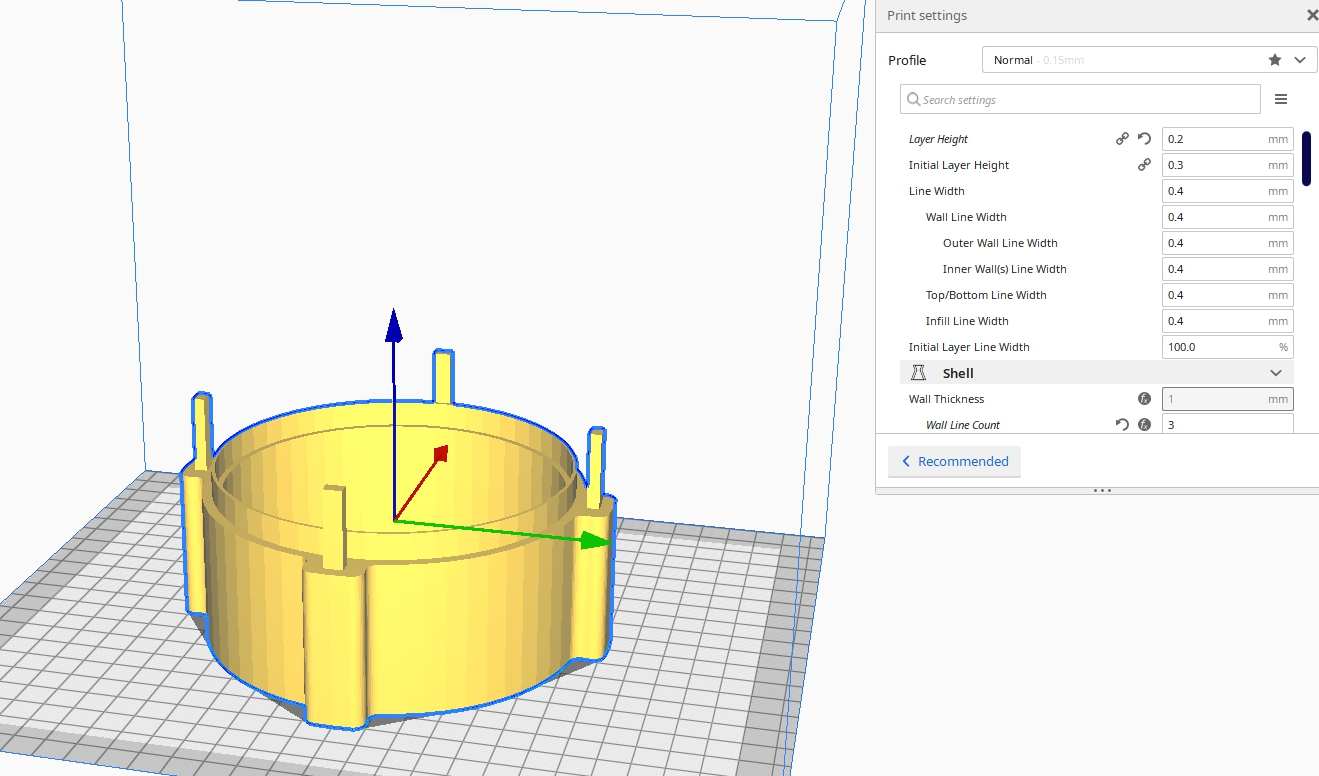

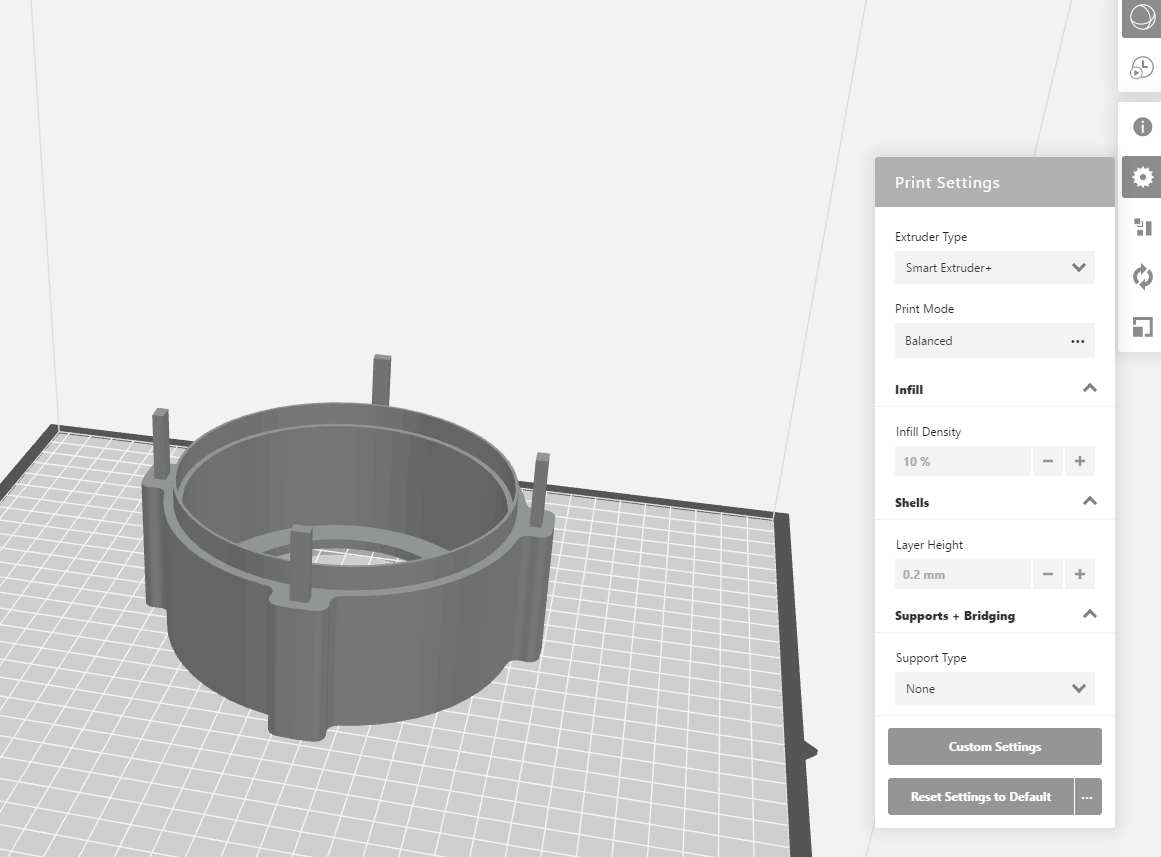

I added stl file for the print in cura software for slicing And kept the layer height to 0.2mm and 15% infill initially

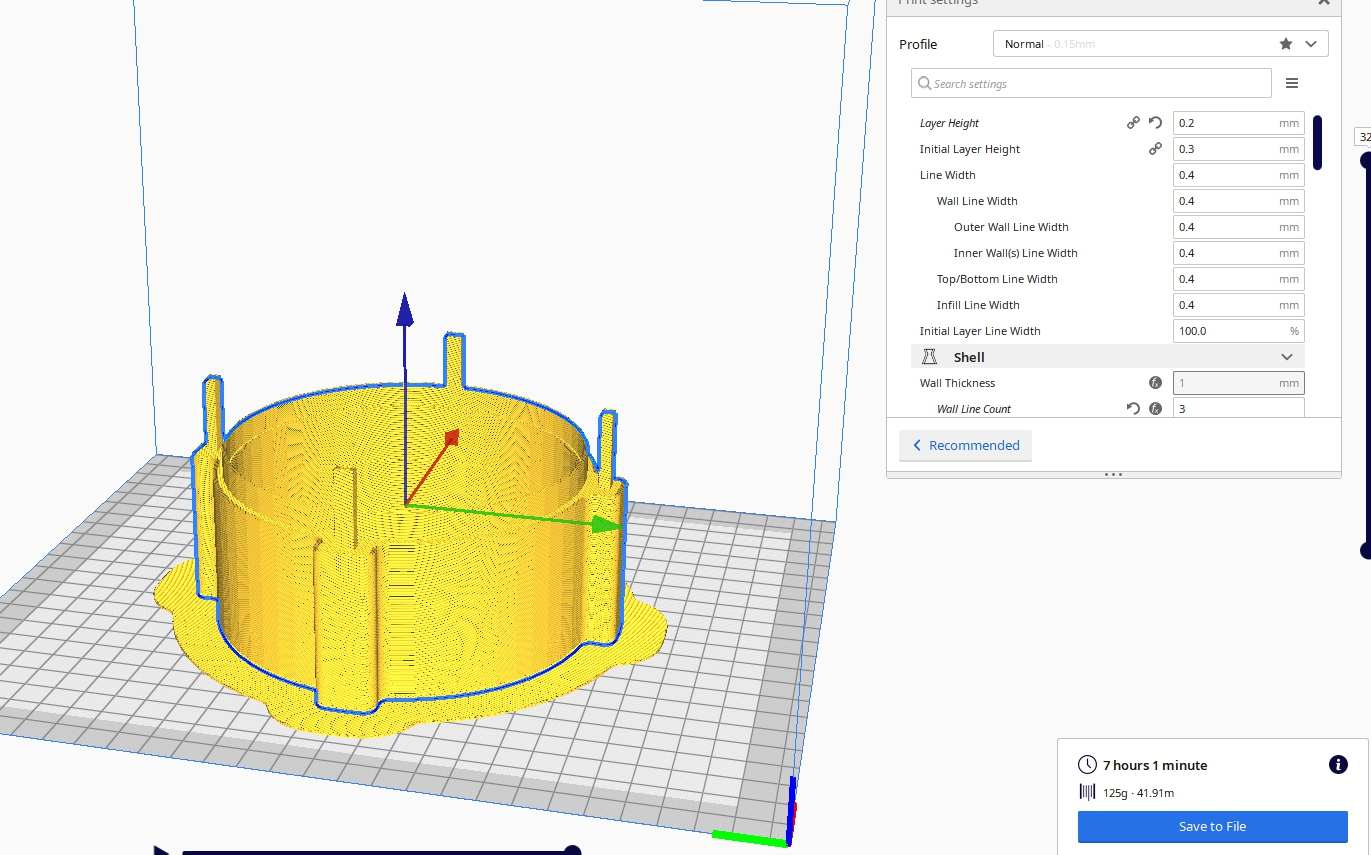

Then i saw that it was taking 7 hours and i thought it is too much for only a test print si i increased the layer height to 0.3 mm and reduce infill to 10% nd got a print around 5hr 30min , si i printed it

I was not happy with the quality as my anet a2 is a DIY printer and i say tha there is merging of 2 layers at some point du to lack f bed levling on my side so i decided not to work on my printer for my particles

Plus i saw that it is very difficult to let the printer work for 5 hrs , during electricity cut

You can see the point on the bottm layer where it merged

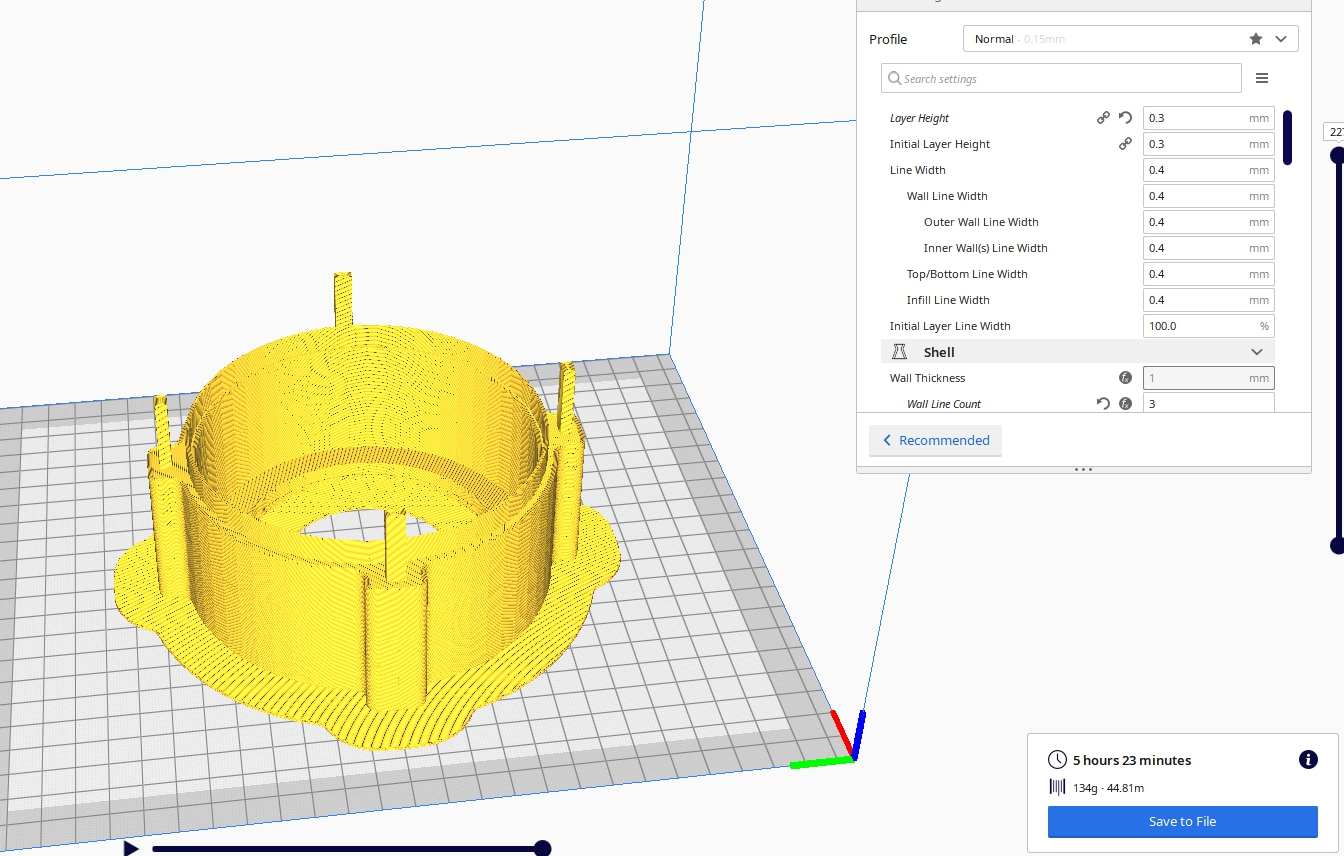

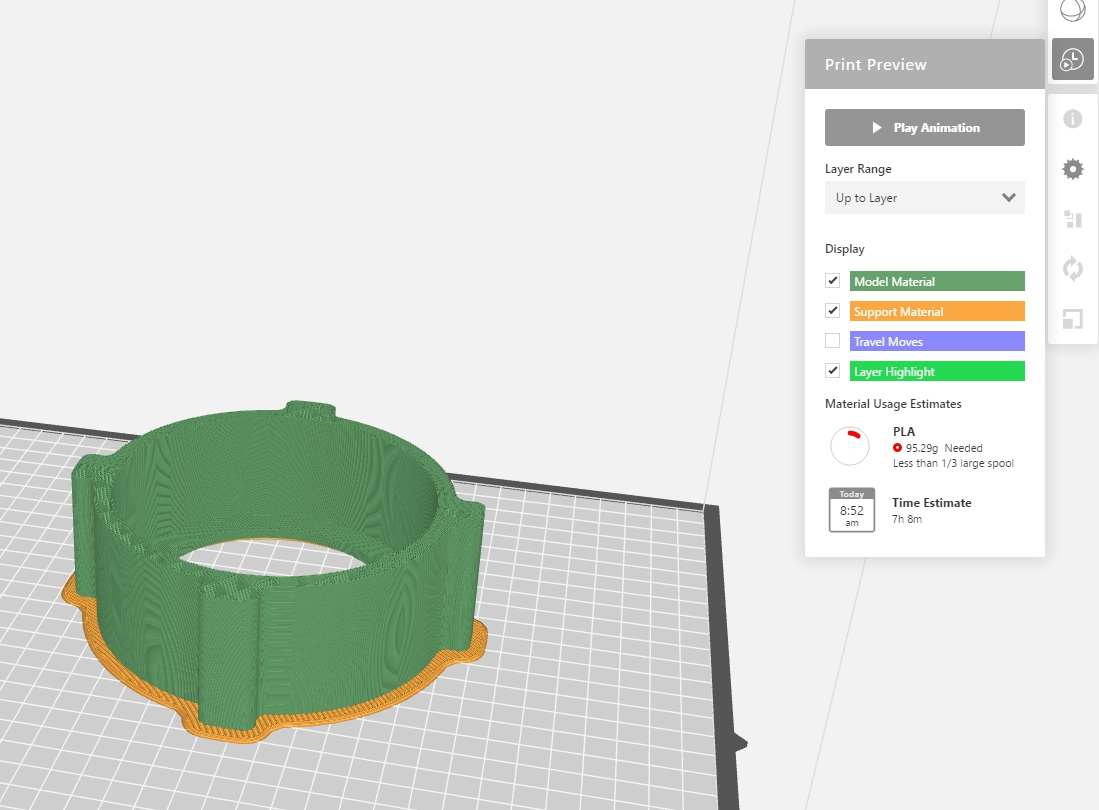

Then i switched ti makerbot Z18 , it is a very good printer at our lab so i though it should be better to print from a good calibrated printer

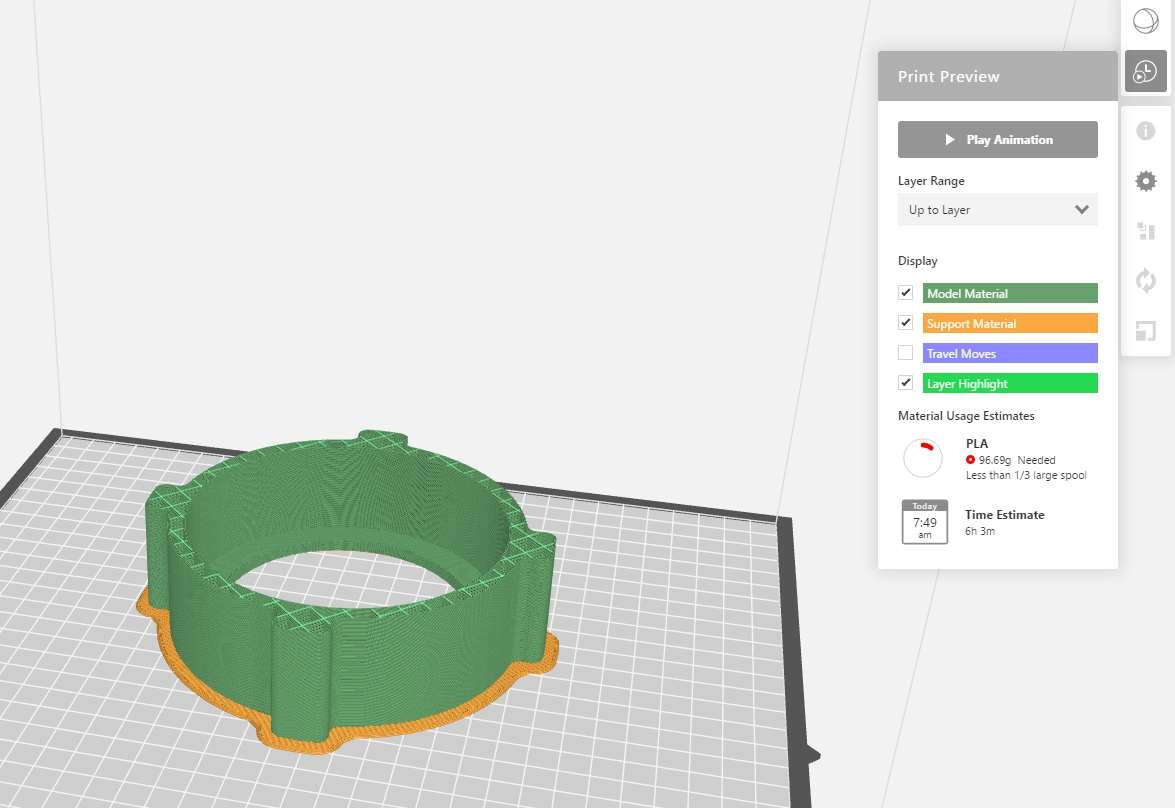

I saw the same result as for 0.2mm layer height and 15% infill , it shows the same time so i thought i should try

Like last time i again increased the layer height to 0.3mm and the build time reduces

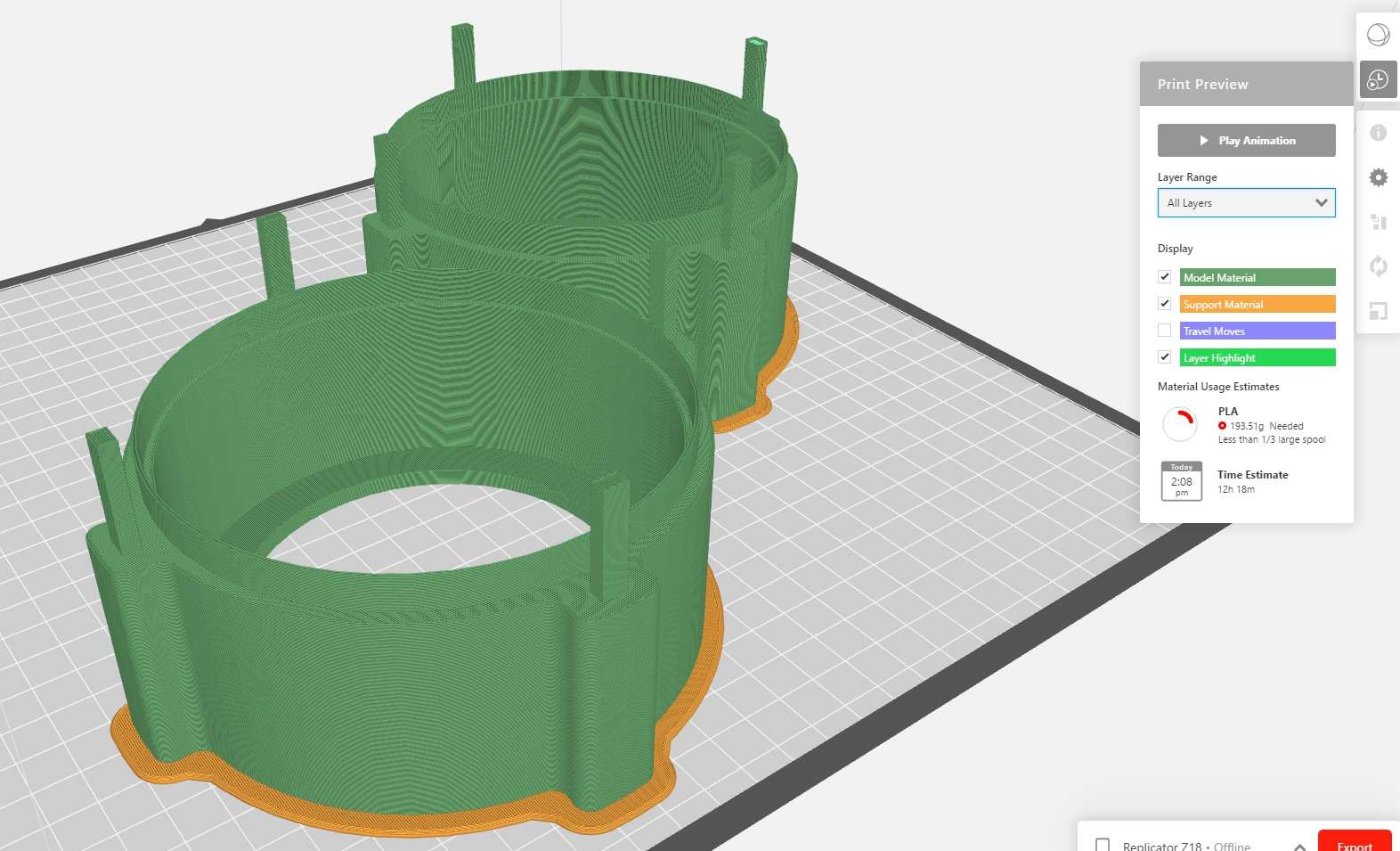

So i added the 2 pieces a tones to print

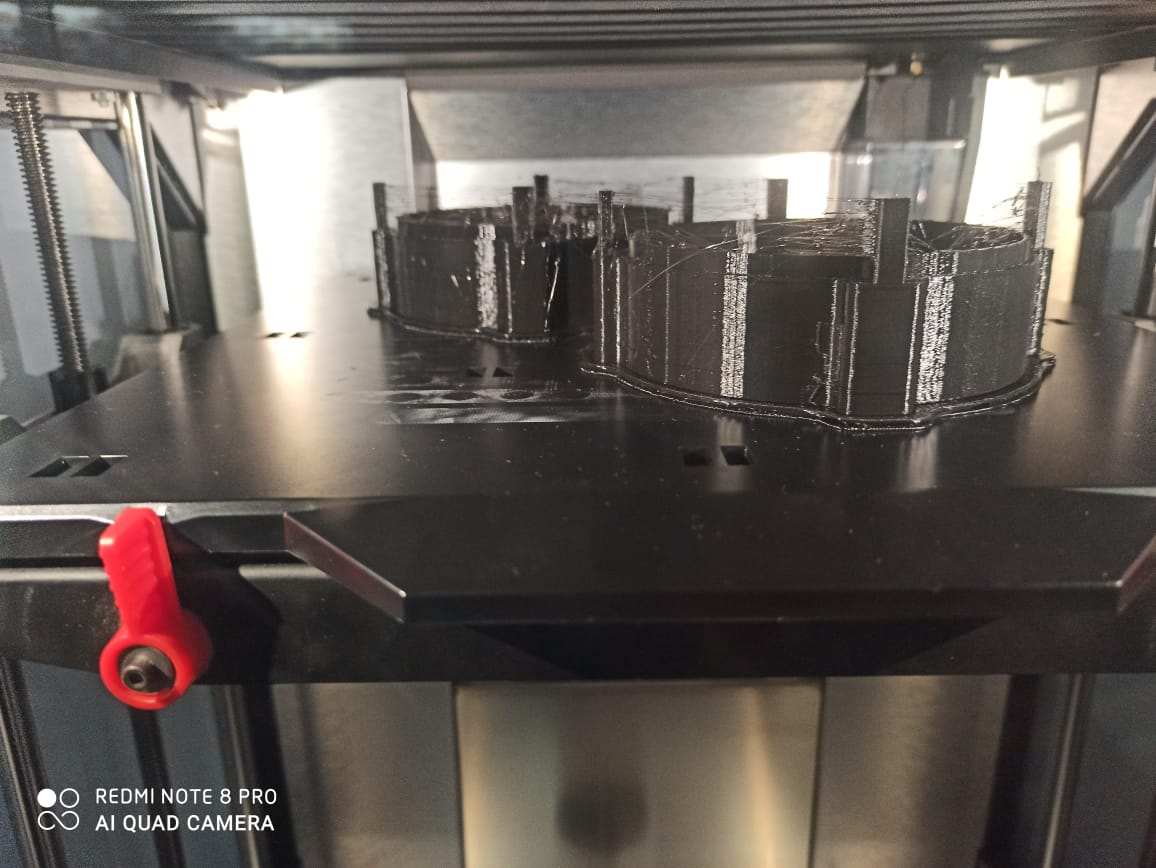

You can see the print after 12hrs

I was not happy with qaulity as n it has lots of strings and there was no smoothness here , my instructor told me that this happened because of the old hot end and there is someamount of material stuck in nozzle

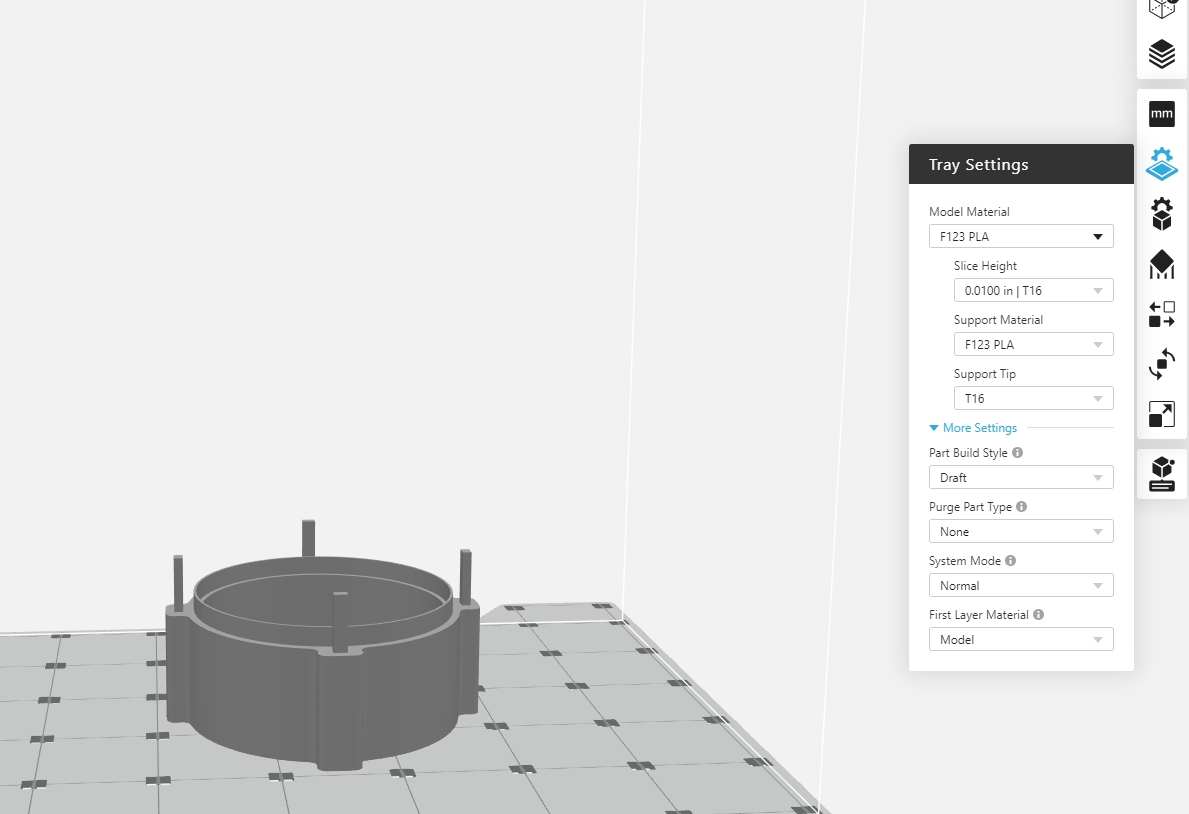

So i needed to switch to 3 printer i.e stratasys f370 , it is a very good printer and can give highest finish possible ,

but like always there was again a problem , that our machine lack of soluble support material , so iwas required to work with only pla

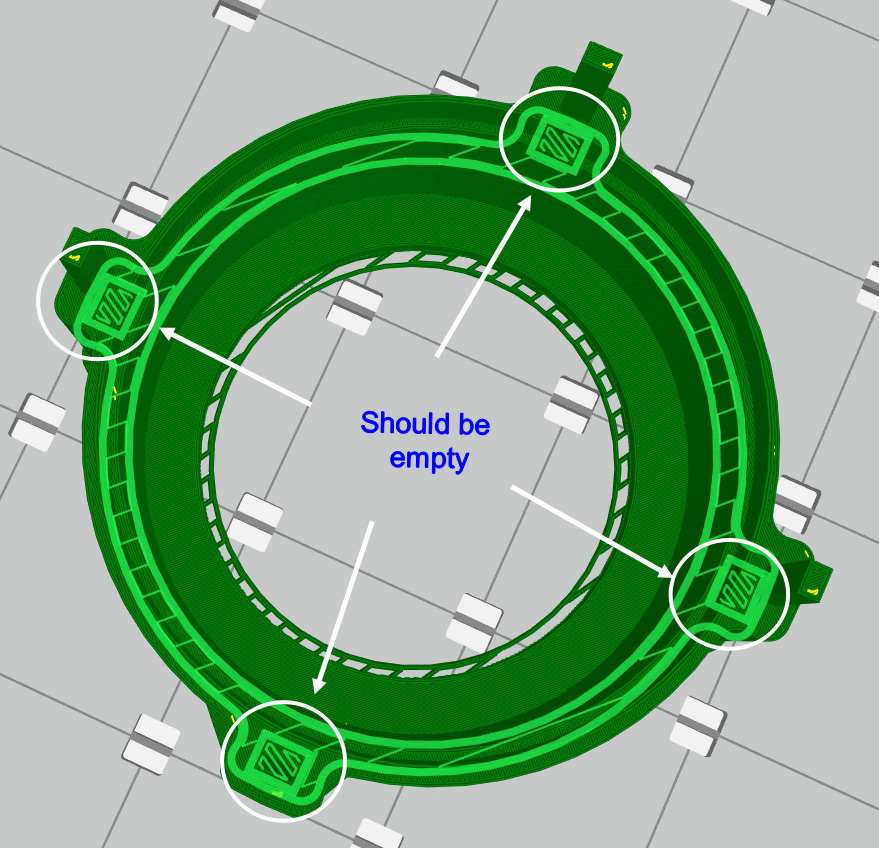

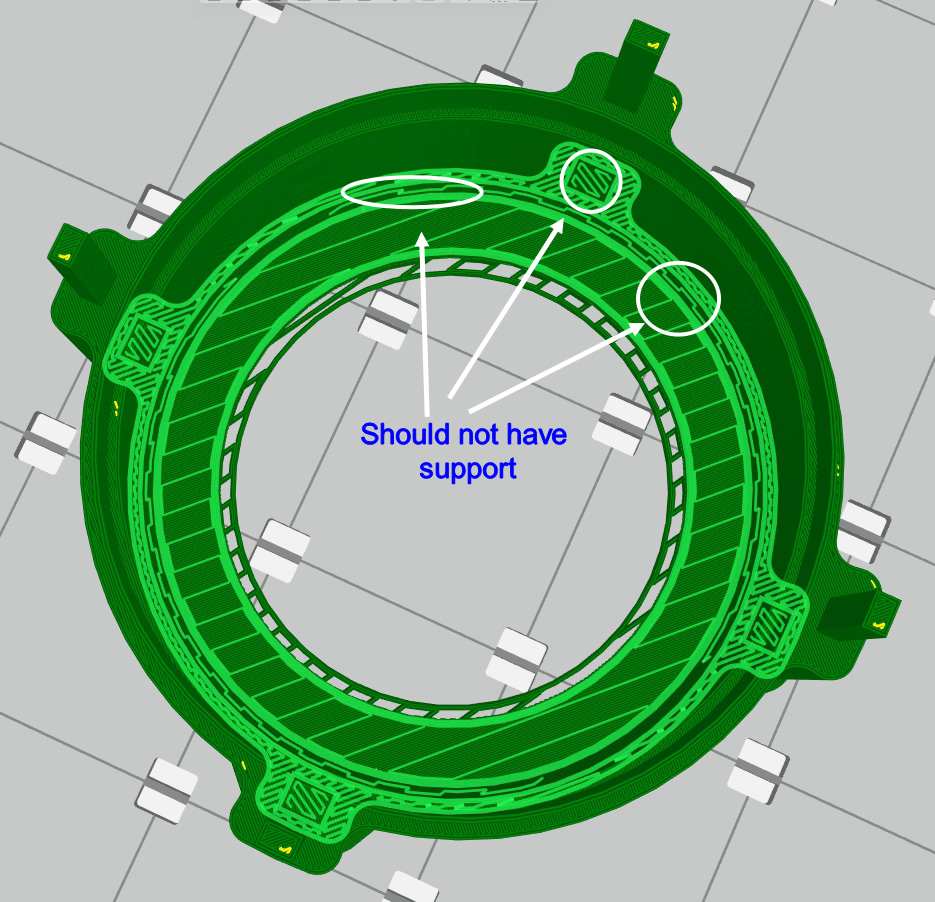

This is the sliced image of the part

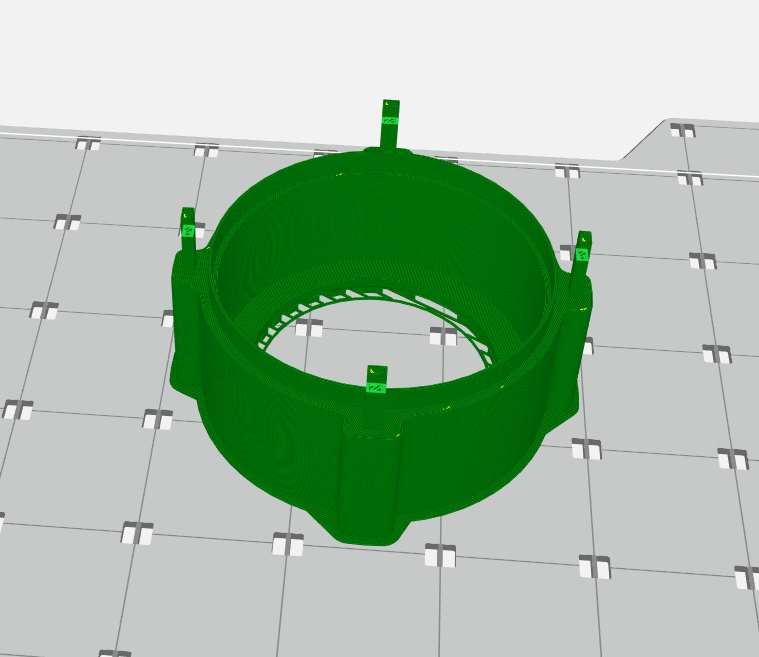

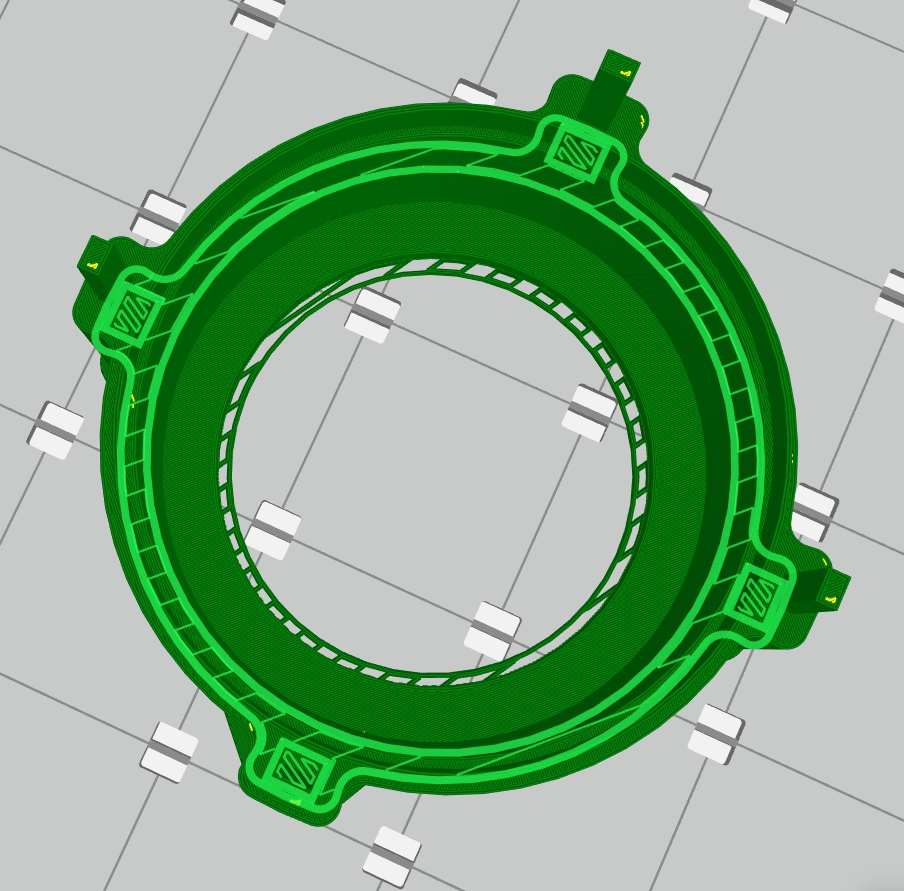

When i looked closely i spotted that the slicer software grabcad in the case of pla material doesnt ask about the how much support we want to give , which posses a huge problem

If you closely look on these parts , these were meant to be hollow but they have support building in them which was not shown in any other software slicer

This effects the interlocking capability of my modules so i was only print 1 piece from stratsys which unconviniently i have to place at the bottom

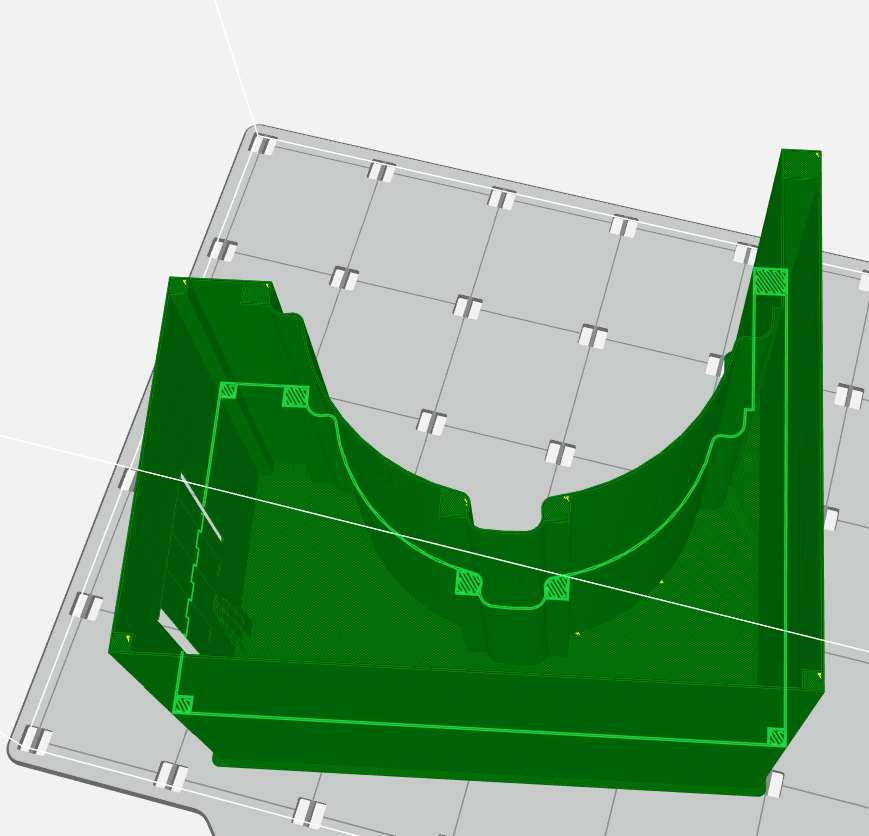

Time to print the electronic boxe , this was a long print due to its big geometry , it took 9hrs 30min to print this , but the mateial consumption was realy nominal

Then i printed its cap

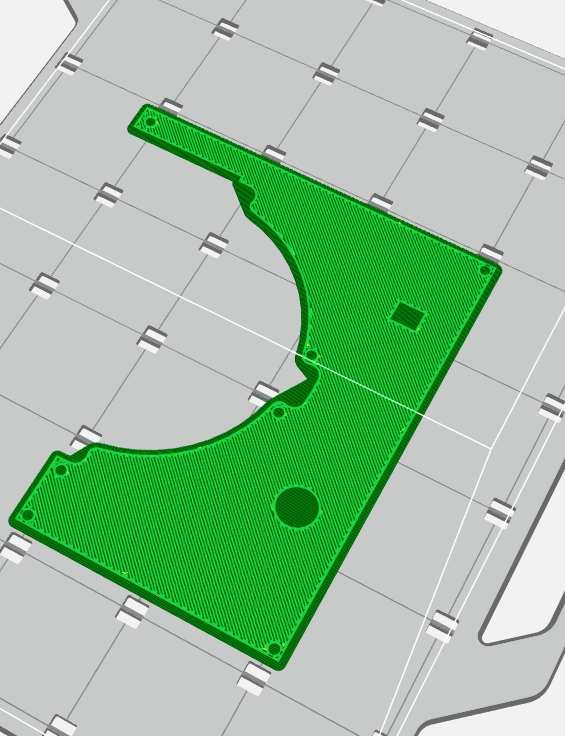

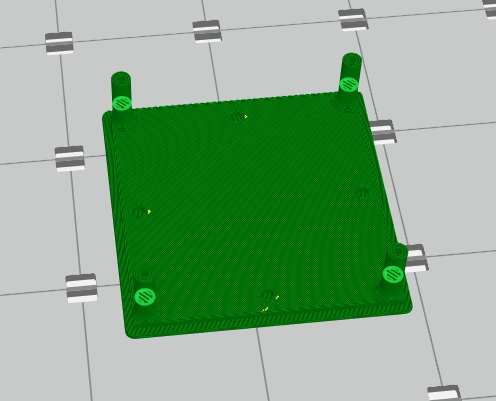

This is a pcb mount which i printed so i can elevate the pcb